[Japanese]

�@�����H�Ƒ�w�@�y���������@�E�F�u�T�C�g

�i2022�N4��11���ȍ~�́C�����炪�����ȃE�F�u�T�C�g�ƂȂ�܂��j

�@URL: https://sites.google.com/view/geotech-cv-titech/

[English]

�@Website of the Soil Mechanics and Geotechnical Engineering Group ,

Tokyo Institute of Technology

�@(The site here will not be updated.

The site below is the official one on and after April 11th, 2022�j

�@URL: https://sites.google.com/view/geotech-cv-titech/

Introduction

�u�y�����v�́A�������Ƃ̌������P�ʂł͂Ȃ��`���I�ɃO���[�v�Ƃ��Ċ����E�s�����s���Ă��茻�݂́A�y�؊��H�w�n�̖k�l�A�|���A�����A�}�Ԍ������̌v4�������A���v��35���قǂ̑吨�̋����E�w������̂Ɋ������Ă���B

�@���N9���ɂ͈ɓ����s�A3���㔼�ɂ͑��Ɨ��s�ƔN2��̗��s���s���Ă���ق��A���N�H�ɂ̓W�I�e�N�O��t�ƌĂ��y�؊w��n�Ռ^�O���[�v�R�̃o���[�{�[������֓����ӂ̑�w�R�ōs����y�����\�t�g�{�[�����A�S�������Z�p�������Ƃ̃T�b�J�[�R�����Ȃǂ��̑��l�X�ȃC�x���g�ɎQ�����Ă���B

�@�����āA���N1���ɂ͑S�y��������ї��OB���������y���������V�N����s���Ă���B�����40�N�ȏ㑱���Ă���A���N100���ȏ�̎Q���҂ŁA�N�������A�g��ł���B

The Soil Mechanics and Geotechnical Group in Tokyo Tech is currently composed of research laboratories individually supervised by Prof. Masaki Kitazume, Assoc. Prof. Jiro Takemura, Prof. Akihiro Takahashi and Assoc. Prof. Kiyonobu Kasama. Although the Group has four distinct laboratories, most activities, academic or otherwise are held as a group, with around 30 active members.

Traditional events include a bi-annual laboratory trip to Izu, every September. A trip is also held late March as a parting event for the laboratory�fs new graduates.

The Group also participates in many sporting events and tournaments with other universities and institutes namely the softball and volleyball tournaments during the Fall Semester with other soil laboratories in the Kanto region, and various other football games against the Railway Technical Research Institute.

At the start of each year, the group welcomes back its former students wherein over 100 alumni from the 40-year history of the laboratory participates, enforcing a strong connection with its current members.

Page TopAbout Research

�������ł͗l�X�ȓy���A�n�Օ���̌������s���Ă���B�ŋ߂ł͒n�Չ��ǁA�͐��h�̐Z�����C��b�A�[����b�̑ϐk���A�t��Ɋւ��錤�����p���I�ɐi�߂Ă���B

���A�����̌����͎�ɉ��S�͌^���u��p���čs���Ă���B�y���������ł͏��a45�N�ɉ��S�͌^�������u (��About Centrifuge)�����Ă���A���S���u��p����������40�N�߂��p�����Ă���A��ɐ��E�I�ɍ������x�����ێ����Ă���B

�ŋ߂̌����e�[�}�ɂ��Ă͊e�N�̌����^�C�g���̃y�[�W���Q�Ƃ��Ă��������B(��Research)

Currently, the Tokyo Tech soil laboratory is one of the few university-laboratories in Kanto region to own a beam type centrifuge machine (��About Centrifuge). The centrifuge technology, which was first instated in the laboratory in the 1970s, has continued to be employed in most research endeavors of students from the undergraduate school to the graduate school, giving a competitive-edge in the quality of their research output.

As far as research interests are concerned, the laboratory has produced and is currently involved with a wide-ranging soil mechanics and geotechnical engineering problems. Ongoing research involves on topics of earthquake resistance of underground structures, shallow and deep foundations, liquefaction countermeasures, intermediate soil behaviors. For more information about the research themes, visit the research tab in our webpage.(��Research)

Page TopAbout Centrifuge

�ʏ�A�n�Ղ̋����͂��̎��d�A�܂��͂��̏�̍\�����̏d�ʂɂ����̂���ȗv���ł���B�������A���n�Ղ����̂܂k�������͌^�ł͗͊w�I�ɁA���A�w�I�ɂ��������镨�ł͂Ȃ��A���ۂ̋����Ƃ͑傫���قȂ�B�����ŁA���S���u��p�����^�͌^�ɉ��S�����x����p�����邱�Ƃɂ���āA�k�������͌^�ł������Ɠ��l�̒n�Չ��͂��Č����邱�Ƃ��\�ł���B�n�ՍH�w�̕���ɂ�����A�n�Ջ����ϑ��̂��߂̈��@�Ƃ��āA�ߔN�A�}���ɔ��B���Ă�������ł���A�����H�Ƒ�w�y���������ł�1970�N���瓱�����ꌻ�݂܂�40�N�ȏ�̗��j���ւ�B�܂��A�N�e�B�u������f�y��(1998)�A����-����2�����U����(2000)�A����-����-���[�����g3�����W���b�L(2002)�Ȃǂ̊e�푕�u�𐢊E�ɐ�삯�ĊJ�����A�n�ՍH�w�ɂ�����l�X�Ȗ��̉𖾂Ɏ��g��ł���B

Mark�V

Physical modelling plays an important role in geotechnical engineering specifically in the investigation of development process of phenomena, parametric studies, investigation of a new phenomenon and verification of analytical or numerical methods.

However, it could not be simulated properly with model tests under an ordinary gravity field, as self-weight is dominant load in geotechnical engineering problems and confining pressures generated by it govern behaviour of soil mass.

In order to replicate the gravity-induced stresses of a prototype in a 1/n reduced model, it is necessary to test in a high gravitational field n times larger than that of prototype. A centrifuge is thought to be a most convenient tool to make a high acceleration field in a model. This idea was applied for the first time in 1930s, in the field of the geotechnical engineering by P.B.Bucky (1931) and G.I.Pokrovsky (1932). Since then, a number of geotechnical centrifuges have been installed in research institutes all over the world. Centrifuge modelling has become one of the powerful tools for physical modelling.

In Japan, the first geotechnical centrifuge was built by Prof. Mikasa in 1965. The second centrifuge was constructed at Tokyo Institute of Technology a few years later in 1970 by Prof Yamaguchi. It was called Mark I Centrifuge. �gMark I�h is now working at Utsunomiya University. In 1981, the second centrifuge machine called �gMark II�h was completed in the laboratory. This machine is now with Saitama University.

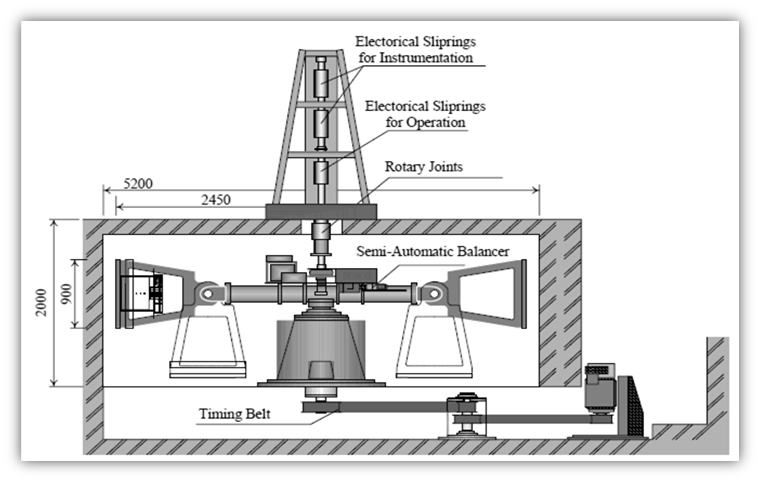

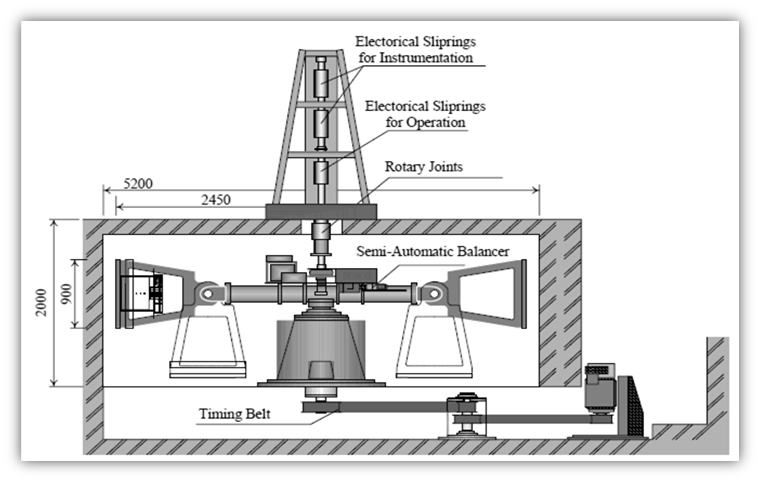

Currently, the in-house centrifuge machine in the laboratory is called �gMark III�h which is a beam type centrifuge having a pair of parallel arms that hold platforms on which the model container and a weight for counterbalance are mounted as shown in the following figure. The radius of rotation is 2.45m, which is the distance from the rotating shaft to the platform base. The surface of the swinging platform is always normal to the resultant acceleration of the centrifugal acceleration, ng, and Earth's gravity. Specifications of the centrifuge are summarized in the following table.

Mark III Specifications |

||

Radius |

Platform radius |

2.45m |

Effective radius |

2.0 - 2.2m |

|

Platform dimensions |

Width |

0.90m |

Depth |

0.90m |

|

Maximum height |

0.97m |

|

Capacity |

Maximum payload |

50g.ton |

Maximum number of rotations |

300rpm |

|

Maximum payload at 80-g |

600kg |

|

Electrical slip rings |

For operation |

18 chs |

Rotary joints |

Number of ports for air and water |

2 |

Working pressure for air and water |

1MPa |

|

Number of ports for oil |

2 |

|

Working pressure for oil |

21MPa |

|

Optical rotary joints |

Number of ports |

4 |

For data acquisition, two types of signal transmission methods are used. One is classical electrical slip rings. Transducers are connected to the slip rings through a junction box and signals are transferred to amplifiers on the laboratory floor. The other type is an optical rotary joint. Transducers are connected to signal conditioners on the centrifuge. Analog signals from the transducers are amplified there and then are converted to digital signals by A/D converters. Gains and the other conditions of the signal conditioners can be controlled by a PC on the lab. floor. The digital signals are transferred to the PC on the lab. floor through the optical rotary joint.

A hydraulic rotary joint with maximum pressure of 20.5MPa mounted on the centrifuge is used for charging and discharging oil to the centrifuge during spinning of the centrifuge. Two four-liter hydraulic accumulators are mounted on the centrifuge to satisfy the required flow rate of the pressurized oil for the active type shear box and a horizontal--vertical 2D shaker.

Shear how active and (1998), horizontal - Shaking in two directions perpendicular (2000), horizontal - vertical - Jack three components Moment (2002) first developed the world's various devices, such as the various problems in geotechnical engineering working on the elucidation of.

Page TopHow to Join

���H��y�E���H�w�n����y���������ɏ�����������

�@�y�����ɋ��������������A�܂���]�̌����������߂��˂Ă�����A�������܂ł��炵�Ă��������B

�S���̐搶�ɑ��k�������y�Ɍ������̗l�q�ȂǕ����Ă݂Ă��������B

���[���ł̎���⌤�����K��̃A�|�C���g�͂��ł��t���Ă��܂��B

����w�A���H��̑���U����y���������ɏ�����������

�@��w�@�y�E���H�w�n�̉@���ɍ��i���Ȃ���Ȃ�܂���B�y�؍H�w�̈�ʓI�Ȓm����₤��肪�o�肳��܂��B�ڂ����͓���w�y�ѐ�U�̃z�[���y�[�W�̓����֘A�̃y�[�W���������������B�܂��A����⌤�����K��͂��ł��t���Ă��܂��B

(���y�؍H�w��U�z�[���y�[�W�� ���������̏ꏊ �����[�� )

Page Top